- How to Choose Condensing Units and Its Size

- Add China Cold Room for You

- Youcool Refrigeration Solutions for Variety of Applications

- Protect Your Walk-in Freezer or Cooler

- The Importance of Walk in Freezer Doors for Refrigeration Units

- Several Steps of Design China Cold Room

- China Cold Room - Best Industrial Refrigeration Solutions

- Why You Need China Cold Room

- The Benefits of Commercial Walk In Freezer

- Different Categories of Refrigerated Warehouse

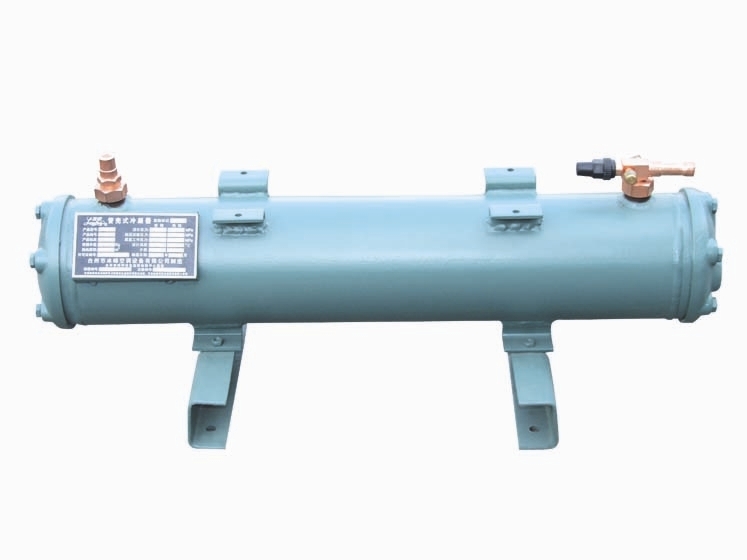

Shell and Tube Type Evaporators

Features

The product features as below:

1. They are designed and produced strictly accorded with the National Standard and supervised under the National authority. We have specially manufacturing license for it.

2. The inner copper pipe is high efficient grooved type.

3. The product has been tested under the air pressure and water pressure, with 1.15MPa for shells and 1.9MPa for pipes.

4. Qualified clean process makes its cleanness good to all type of refrigerants.

5. The product has water drainage devices, for protect it from freezing side in the winter.

Overheat pipes are employed to ensure efficiency.

6. Good quality welding makes it no debris and impurities left.

7. Overheat pipe are employed to ensure efficiency.

Design Condition

Temperature of chilled water in: Ti=12℃

Temperature of chilled water out: T0=7℃

Evaporation Temperature: Te=2℃

Water velocity: V=0.7-1.5m/s

GZ Series list

|

Model |

Capacity kW |

Water flow m3/h |

Overall size |

Installation size (mm) |

Pipe dia. (Ø mm) |

|||||||||

D |

T |

T1 |

B |

H |

F |

A |

S |

C |

D |

G |

w |

|||

|

GZ-05 |

17.5 |

3 |

168 |

1060 |

914 |

230 |

202 |

180 |

600 |

90 |

22 |

16 |

3/8 |

11/4″ |

|

GZ-08 |

28 |

5 |

219 |

1060 |

914 |

250 |

253 |

200 |

600 |

90 |

28 |

16 |

3/8 |

11/4″ |

|

GZ-10 |

35 |

6 |

219 |

1060 |

914 |

250 |

249 |

200 |

600 |

90 |

35 |

16 |

3/8 |

11/2″ |

|

GZ-15 |

53 |

9 |

219 |

1350 |

1200 |

250 |

244 |

200 |

800 |

90 |

42 |

22 |

3/8 |

2″ |

|

GZ-20 |

70 |

12 |

273 |

1350 |

1200 |

350 |

298 |

300 |

800 |

100 |

54 |

22 |

3/8 |

2″ |

|

GZ-25 |

88 |

15 |

273 |

1650 |

1500 |

350 |

298 |

300 |

1200 |

100 |

54 |

28 |

3/8 |

2″ |

|

GZ-30 |

105 |

18 |

273 |

1750 |

1600 |

350 |

298 |

300 |

1200 |

100 |

54 |

28 |

3/8 |

2″ |

|

GZ-35 |

122 |

21 |

273 |

1950 |

1800 |

350 |

310 |

300 |

1400 |

120 |

54 |

28 |

3/8 |

21/2″ |

|

GZ-40 |

140 |

24 |

273 |

2150 |

2000 |

350 |

310 |

300 |

1400 |

120 |

54 |

35 |

3/8 |

21/2″ |

|

GZ-45 |

158 |

27 |

325 |

2150 |

2000 |

400 |

362 |

350 |

1400 |

120 |

54 |

35 |

3/8 |

21/2″ |

|

GZ-50 |

175 |

30 |

325 |

2150 |

2000 |

400 |

355 |

350 |

1400 |

120 |

54 |

35 |

3/4 |

3″ |

|

GZ-60 |

210 |

36 |

355 |

2350 |

2000 |

450 |

355 |

380 |

1400 |

120 |

80 |

35 |

3/4 |

3″ |

|

GZ-70 |

245 |

42 |

355 |

2350 |

2000 |

450 |

355 |

380 |

1400 |

150 |

80 |

35 |

3/4 |

3″ |

|

GZ-80 |

280 |

49 |

355 |

2600 |

2400 |

450 |

371 |

380 |

1600 |

150 |

80 |

35 |

3/4 |

4″ |

|

GZ-90 |

315 |

55 |

355 |

2800 |

2600 |

450 |

371 |

380 |

1600 |

150 |

80 |

35 |

3/4 |

4″ |

|

GZ-100 |

350 |

60 |

405 |

2800 |

2600 |

550 |

417 |

440 |

1600 |

150 |

80 |

35 |

3/4 |

5″ |

|

GZ-120 |

420 |

73 |

405 |

2800 |

2600 |

550 |

417 |

440 |

1600 |

150 |

80 |

35 |

3/4 |

5″ |

|

GZ-130 |

455 |

80 |

405 |

2800 |

2600 |

550 |

417 |

440 |

1600 |

150 |

80 |

54 |

3/4 |

5″ |

|

GZ-140 |

490 |

85 |

405 |

3210 |

3000 |

550 |

405 |

440 |

1800 |

200 |

80 |

54 |

1″ |

6″ |

|

GZ-150 |

525 |

90 |

457 |

3210 |

3000 |

620 |

455 |

550 |

1800 |

200 |

80 |

54 |

1″ |

6″ |

|

GZ-180 |

630 |

110 |

457 |

3210 |

3000 |

620 |

455 |

550 |

1800 |

200 |

105 |

54 |

1″ |

6″ |

|

GZ-200 |

700 |

120 |

530 |

3510 |

3300 |

680 |

525 |

600 |

1800 |

200 |

105 |

54 |

1″ |

6″ |

|

GZ-250 |

875 |

150 |

570 |

3510 |

3300 |

700 |

555 |

650 |

1800 |

220 |

105 |

54 |

1″ |

6″ |

|

GZ-300 |

1050 |

180 |

570 |

3810 |

3600 |

700 |

520 |

650 |

1800 |

220 |

134 |

80 |

1″ |

8″ |

Overall appearance and size

GZ(single system)Overall appearance and size

G Z(double system)Overall appearance and size

GZU series

|

Model |

Capacity KW |

Water flow |

Overall size |

Installation size |

Liquid in |

Gas out |

Water pipe |

Water path |

|||||||

|

m3/h |

T |

T1 |

D1 |

D |

H |

A |

A1 |

F |

F1 |

a |

b |

w1/2 |

|||

|

GZU-05 |

14 |

2.5 |

785 |

500 |

240 |

168 |

285 |

350 |

160 |

200 |

150 |

¢19 |

¢22 |

DN25 |

4 |

|

GZU-08 |

25 |

4.5 |

988 |

700 |

240 |

168 |

285 |

500 |

200 |

200 |

150 |

¢22 |

¢28 |

DN40 |

2 |

|

GZU-10 |

31 |

5.5 |

1140 |

850 |

240 |

168 |

285 |

600 |

200 |

200 |

150 |

¢22 |

¢28 |

DN40 |

2 |

|

GZU-12 |

35 |

6 |

1140 |

850 |

290 |

219 |

340 |

600 |

200 |

250 |

200 |

¢22 |

¢28 |

DN40 |

2 |

|

GZU-15 |

42 |

7.5 |

1450 |

1130 |

290 |

219 |

340 |

750 |

220 |

250 |

200 |

¢22 |

¢42 |

DN50 |

2 |

|

GZU-20 |

62 |

11 |

1565 |

1250 |

290 |

219 |

340 |

1000 |

230 |

250 |

200 |

¢22 |

¢42 |

DN50 |

2 |

|

GZU-30 |

90 |

15.5 |

1825 |

1500 |

290 |

219 |

340 |

1000 |

250 |

250 |

200 |

¢35 |

¢54 |

DN65 |

2 |

|

GZU-40 |

120 |

21 |

2410 |

1980 |

290 |

219 |

340 |

1200 |

300 |

300 |

250 |

¢35 |

¢54 |

DN65 |

2 |

|

GZU-50 |

155 |

27 |

2610 |

2030 |

360 |

273 |

376 |

1500 |

475 |

300 |

250 |

¢35 |

¢67 |

DN80 |

2 |

|

GZU-60 |

210 |

36 |

2610 |

2030 |

360 |

273 |

376 |

1500 |

475 |

300 |

250 |

¢35 |

DN80 |

DN80 |

2 |

|

GZU-70 |

230 |

40 |

3030 |

2400 |

360 |

273 |

376 |

1500 |

650 |

300 |

250 |

¢35 |

DN80 |

DN80 |

2 |

|

GZU-80 |

280 |

49 |

3030 |

2400 |

410 |

325 |

510 |

1500 |

650 |

400 |

320 |

¢35 |

DN80 |

DN100 |

2 |

|

GZU-90 |

320 |

56 |

3030 |

2400 |

410 |

325 |

510 |

1500 |

650 |

400 |

320 |

¢35 |

DN100 |

DN100 |

2 |

|

GZU-100 |

350 |

62 |

3030 |

2400 |

410 |

325 |

510 |

1500 |

650 |

400 |

320 |

¢35 |

DN100 |

DN100 |

2 |

|

GZU-110 |

385 |

68 |

3030 |

2400 |

410 |

325 |

510 |

1500 |

650 |

400 |

320 |

¢35 |

DN100 |

DN125 |

2 |

|

GZU-120 |

420 |

73 |

3196 |

2570 |

440 |

355 |

535 |

1800 |

530 |

450 |

350 |

¢35 |

DN100 |

DN125 |

2 |

|

GZU-130 |

455 |

80 |

3196 |

2570 |

440 |

355 |

535 |

1800 |

530 |

450 |

350 |

¢35 |

DN100 |

DN125 |

2 |

|

GZU-140 |

490 |

85 |

3196 |

2570 |

440 |

355 |

535 |

1800 |

530 |

450 |

350 |

¢35 |

DN100 |

DN125 |

2 |

|

GZU-160 |

560 |

97 |

3196 |

2570 |

490 |

406 |

560 |

1800 |

530 |

500 |

400 |

¢35 |

DN100 |

DN125 |

2 |

|

GZU-180 |

630 |

110 |

3196 |

2530 |

490 |

406 |

560 |

1800 |

530 |

500 |

400 |

¢35 |

DN100 |

DN150 |

2 |

|

GZU-200 |

700 |

122 |

3196 |

2530 |

490 |

406 |

560 |

1800 |

530 |

500 |

400 |

¢35 |

DN100 |

DN150 |

2 |

|

GZU-220 |

770 |

133 |

3300 |

2630 |

490 |

406 |

560 |

1800 |

530 |

500 |

400 |

¢35 |

DN100 |

DN150 |

2 |

|

GZU-250 |

880 |

152 |

3680 |

3010 |

490 |

406 |

560 |

1800 |

530 |

500 |

400 |

¢35 |

DN100 |

DN150 |

2 |

- Home - About us - New products - Download - News - Feedback - Contact us - Sitemap

- Powered by semcms 4.5 Copyright @ 2009 - 2015

13916430557

13916430557